About BlakerTech

A Legacy of Engineering Excellence.

At BlakerTech, we specialise in designing and manufacturing metal recycling systems engineered to meet the unique demands of every plant and recovery facility.

From our West Sussex, United Kingdom facility, we engineer tailored systems and solutions that maximise non-ferrous metal recovery, improve product purity and quality, enhance productivity across diverse recycling and processing applications, and generate new revenue streams.

Who We Are

As a specialist division of the Blaker Group Ltd, BlakerTech combines decades of engineering heritage with cutting-edge innovation to deliver powerful and efficient metal recycling solutions.

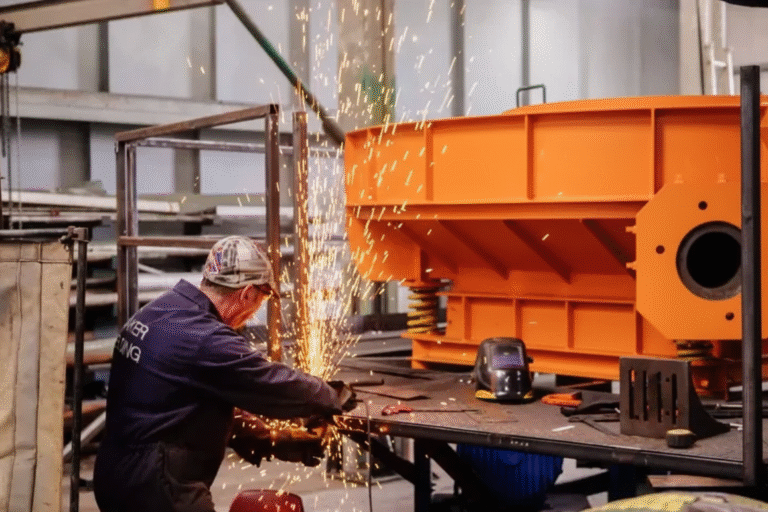

Every system we design and manufacture is built to meet the highest standards of performance, reliability, and durability, proudly engineered and produced in the UK.

Our solutions combine advanced mechanical design, robust construction, and precise material handling to maximise recovery and operational efficiency.

Built to withstand rigorous industrial environments, every system is supported by our team of engineering specialists, ensuring reliability, longevity, and optimal performance. With decades of proven expertise, BlakerTech delivers recycling technology that drives productivity and long-term value for our clients.

The Blaker Tech Approach

We follow a structured, step-by-step process to ensure every project is tailored and successful:

Site Audit & Performance Analysis

Technical & Engineering-Focused

UK Manufacturing & Quality Control

Performance Testing

Installation & Operator Training

Comprehensive, Turnkey System Solutions

Our History

With more than a century of engineering heritage, Blaker has grown from its beginnings in 1886 into a trusted name in British manufacturing and innovation. What started as a London-based engineering workshop has evolved into a respected provider of practical, dependable solutions for industry across the United Kingdom and internationally.

Drawing on decades of experience supporting machinery, metal processing and industrial operations, the business recognised a clear need for more efficient, reliable recovery technologies within the recycling sector. This led to the establishment of BlakerTech in 2019, a dedicated division focused on developing advanced systems for both non-ferrous and ferrous metal recovery.

Since its formation, BlakerTech has supported recycling operators and processing lines with a tailored range of high-performance equipment, backed by exceptional service, technical expertise and dependable on-site support. The Group has built strong, long-standing relationships with customers through its deep knowledge of the metal recycling sector and a continued commitment to its core values of integrity, trust and reliability.

BlakerTech unites the Blaker Group’s extensive engineering experience with modern innovation, delivering robust solutions such as the MagThro eddy current separator and SandFlo density separator. Designed for high throughput, consistent performance and long-term durability, these systems help operators maximise metal recovery while reducing operational costs.

In 2025, Blaker Group Ltd was formally established to unify operations and drive continued investment in facilities, technology and skilled personnel. Today, BlakerTech stands as a central part of the Group’s innovation strategy, continuing the long tradition of problem-solving engineering that has defined Blaker for more than 100 years.

Focused on quality, reliability and sustainable performance, BlakerTech remains committed to delivering industry-leading recycling solutions built on generations of engineering excellence.

Meet the Team

David Middleton

Operations Director

James Ryan

National Sales Manager

Expert Metal Separation Solutions Based in Billingshurst, Horsham

Find us

Unit 1, The Yard

Adversane Lane

Billingshurst, West Sussex

RH14 9EG

Opening Times

Mon – Fri: 8am – 5pm

Sat – Sun: Closed

Call us

01403 783634

Email us

info@blakertech.com