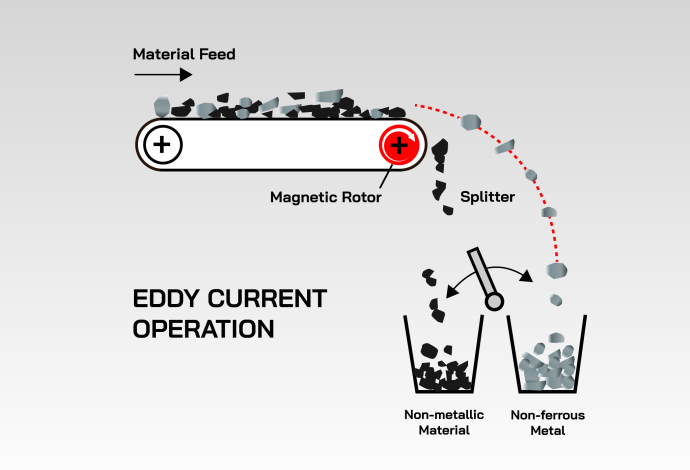

How magnetic separation works in an eddy current separator

Magnetic separation plays a vital role in metal recycling and waste metal recovery, helping to extract valuable non-ferrous metals from mixed material streams.

During the process, ferrous metals are first removed using traditional magnetic systems. The remaining material then passes over a high-speed eddy current separator, such as the MagThro.

Inside the separator, a rapidly rotating magnetic rotor generates constantly changing magnetic fields. These fields induce small electrical currents, known as eddy currents, in non-ferrous metals such as aluminium, copper, and brass. The induced currents create a repelling force that separates non-ferrous metals from other materials, leaving a cleaner, higher-value fraction ready for further processing or reuse.

The MagThro delivers a strong and consistent separation effect thanks to precise magnet polarity alignment and a minimal gap between the rotor and the material being processed. This ensures maximum recovery efficiency and consistent performance in demanding metal recycling environments.

Magnetic separation using an eddy current system is an efficient and proven method that plays an essential role in modern metal recovery and sustainable recycling operations.

Date Published: 16 October, 2025