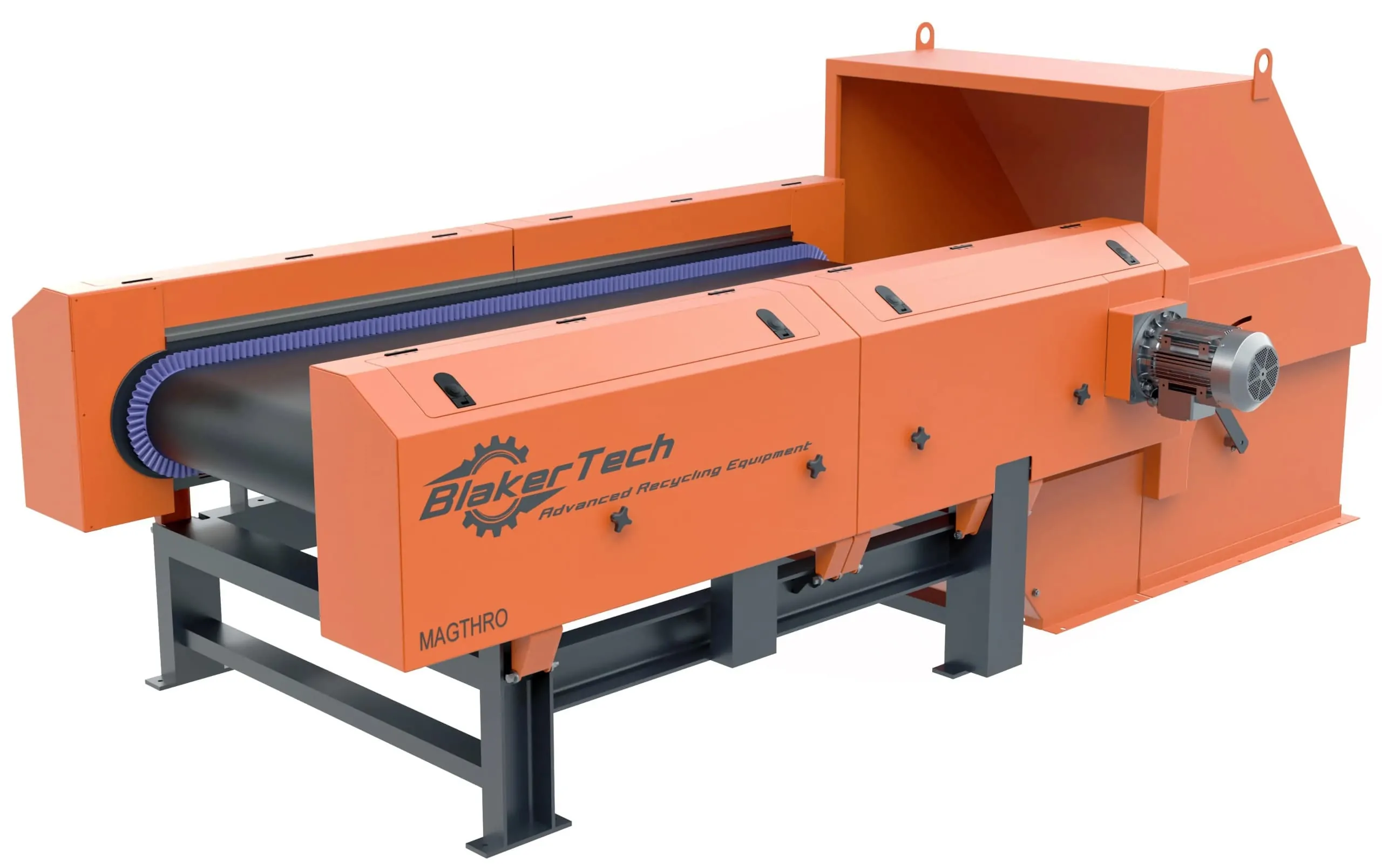

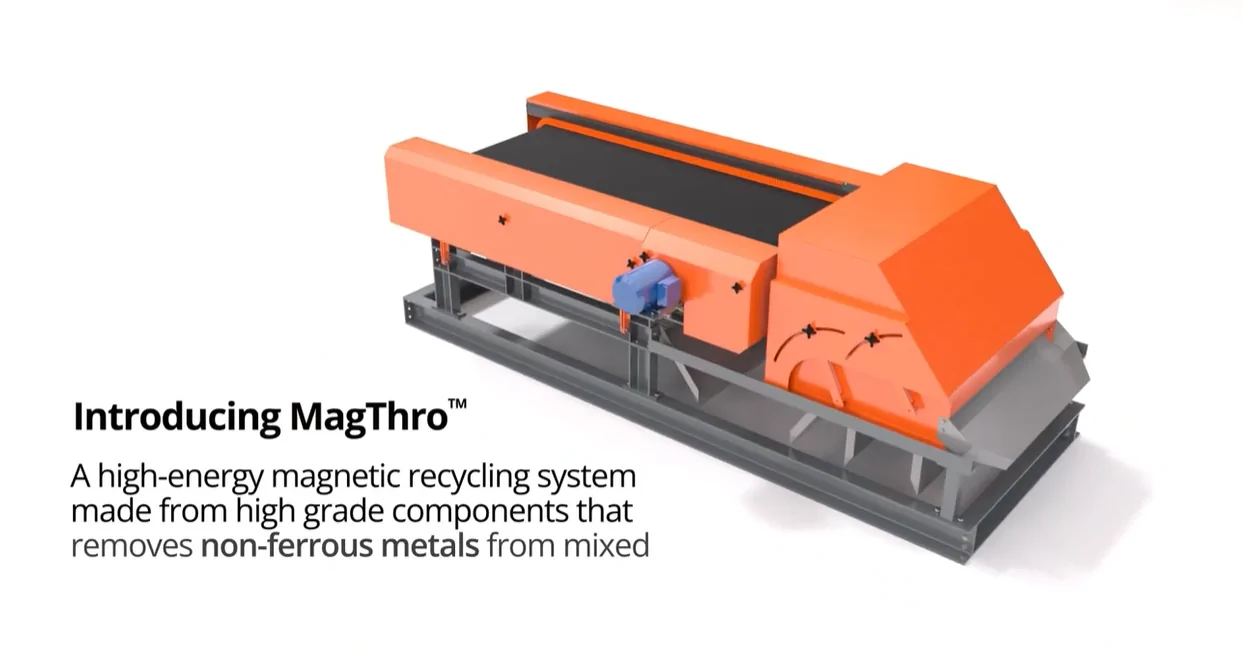

More About MagThro

Made from high-grade components, the MagThro is fitted with 12-pole magnetic shafts. High-performance Neodymium rare earth magnets create a continuous and strong magnetic force that reliably and efficiently separates non-ferrous metals from mixed materials. A three-way splitter sorts the outfall streams into waste, fine/smaller non-ferrous materials and larger non-ferrous materials.

Key sections of the framework are interchangeable, enabling walkways to be attached, while hinged panels provide quick access for routine maintenance. Standard belt widths are: 500mm, 750mm, 1,000mm, 1250mm and 1500mm. The main belt is fully adjustable and can be replaced without disturbing the rotor. The fully adjustable eccentric rotor allows the separation and magnetic force to be altered as necessary to enhance recovery.

A sealed motorised drive drum protects the rotor from foreign objects, and the conveyor belt is driven by Van de Graaff geared drive drums. Quality SKF or Nachi bearings are used for a high quality and smooth performance.

How MagThro Works

Non-ferrous materials are evenly distributed onto a conveyor, which passes over the MagThro. The spinning rotor throws the non-ferrous metals (further than waste materials) into a splitter target, sending the sorted waste and non-ferrous metals downstream to their respective destinations.

The MagThro has an eccentric rotor which can be adjusted to alter the separation/ magnetic force. Ideally, small fragments of non-ferrous materials, screened to 50mm, can be further refined by Blaker Tech’s SandFlo system.

Key features:

- Durable, hard-wearing and robust framework

- Key sections of the framework are interchangeable enabling walkways to be attached – hinged panels provide quick access for routine maintenance checks

- Standard belt widths are: 500mm, 750mm, 1,000mm and 1250mm

- Fitted with high performance Neodymium rare earth magnets

- Options of a two or three-way splitter to suit client requirements

- Wide range of accessories kept in stock including replacement rotors, hoppers, drum magnets, splitters, conveyors, etc.

Read Our Google Reviews

MagThro Case Studies

Your Questions, Answered

Can’t find what you’re looking for? Get in touch with us today.

-

What makes the MagThro eddy current separator different from other separators?

-

MagThro is engineered to deliver reliable and consistent performance in demanding metal recovery environments.

It features high-strength Neodymium magnets that generate a powerful magnetic field, enabling precise separation of non-ferrous metals, such as aluminium, copper, and other non-magnetic materials, commonly found in WEEE, automotive shred, and municipal waste streams.

Built for durability, MagThro has a robust frame and a low-maintenance design, making it ideal for industrial settings where reliability, uptime, and ease of operation are critical.

-

What are neodymium magnets and how are they used in the separation process?

-

Neodymium magnets are rare-earth magnets renowned for their exceptionally strong magnetic fields. In eddy current separation, they are incorporated into the rotor to generate the high-intensity fields necessary to separate non-ferrous metals from mixed material streams.

As materials pass over the rotor, electrical currents are induced in non-magnetic metals such as aluminium and copper. These currents create a repelling force that separates the metals from the rest of the material stream.

The MagThro system includes a three-way splitter that directs output into separate streams for waste, fine non-ferrous metals, and larger non-ferrous metals. The strength of the Neodymium magnets allows effective separation of small particles, even those under 5 mm, providing a clear performance advantage over ferrite-based systems, which can struggle with smaller items such as aluminium fragments or shredded foil.

-

What role does the vibratory feeder play in MagThro's efficiency?

-

A vibratory feeder is essential for optimising the performance of the MagThro eddy current separator. It ensures that incoming material is evenly distributed across the belt in a single-layer, or monolayer, flow.

This consistent feed allows the Neodymium magnet rotor to apply separation forces uniformly, enhancing the accuracy and efficiency of non-ferrous metal recovery. Uneven material distribution can reduce separation performance, particularly when processing mixed or high-volume streams.

-

Is MagThro suitable for high-volume recycling operations?

-

Yes, the MagThro is purpose-built for high-throughput environments where consistency and reliability are critical. It is ideally suited for material recovery facilities (MRFs), scrap metal yards, and e-waste processing centres, providing efficient non-ferrous metal separation.

When paired with a suitable feed system, MagThro can operate for extended periods with minimal downtime. Some customers run their equipment up to 20 hours a day, seven days a week, demonstrating its robust construction and dependable performance in demanding industrial settings.

-

What are the benefits of using rare-earth magnets like neodymium in metal recovery?

-

Neodymium magnets are exceptionally strong and compact, allowing precise separation of even small or low-mass non-ferrous metals. Their high strength also reduces the need for moving parts, lowering energy consumption and maintenance requirements.

-

What types of materials do MagThro separate in real-world applications?

-

- Non‑ferrous metals from mixed waste streams: MagThro uses a high-energy eddy current rotor with Neodymium magnets to separate non-magnetic metals like aluminium, copper, and brass from shredded or mixed material.

- Fine fractions and small particles: Thanks to its powerful rotor and precise three-way splitter, MagThro can recover very small non-ferrous fragments, even under 5 mm, making it ideal for processing shred residue or fines.

- Complex waste streams: The system is particularly effective in handling difficult materials such as printed circuit boards (PCBs), as shown in case studies where non-ferrous metals embedded in mixed plastics and electronics are extracted.

- Automotive shred and ASR (Automotive Shredder Residue): MagThro helps unlock value from ASR, separating metals from plastics, rubber, glass, and other non-metals commonly found in ELV (end-of-life vehicle) processing.

Need More Information?

If you can’t find what you are looking for, then please give me a call on 01403 783634 for a fast, friendly and helpful service.

James Ryan | National Sales Manager