Reliable and efficient metal recovery

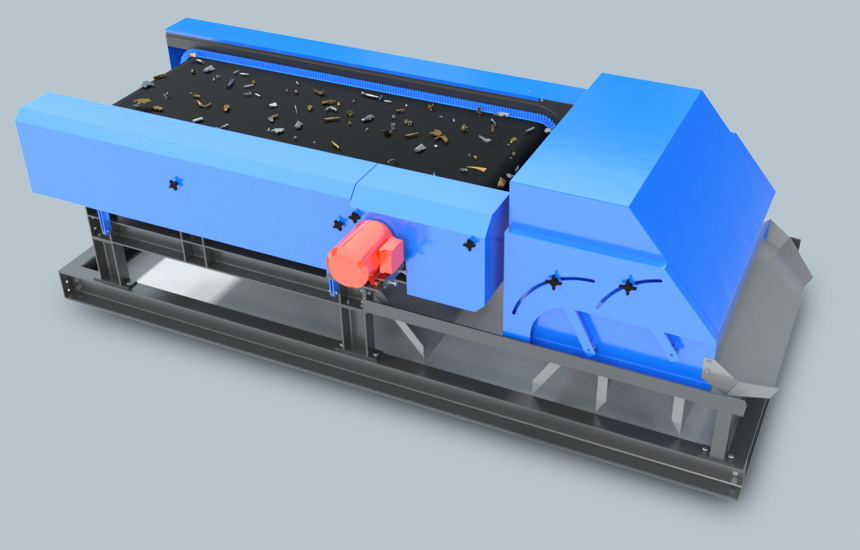

Made from high-grade components, the MagThro is fitted with 12-pole magnetic shafts. High-performance Neodymium rare earth magnets create a continuous and strong magnetic force that reliably and efficiently separates non-ferrous metals from mixed materials. A three-way splitter sorts the outfall streams into waste, fine/smaller non-ferrous materials and larger non-ferrous materials.

Key sections of the framework are interchangeable, enabling walkways to be attached, while hinged panels provide quick access for routine maintenance. Standard belt widths are 500, 750, 1000 and 1250mm. The main belt is fully adjustable and can be replaced without disturbing the rotor. The fully-adjustable eccentric rotor allows the separation and magnetic force to be altered as necessary to enhance recovery.

A sealed motorised drive drum protects the rotor from foreign objects and the conveyor belt is driven by Van de Graaff geared drive drums. Quality SKF or Nachi bearings are used for a high quality and smooth performance.

MagThro is built by BlakerTech at their manufacturing facility in the South East of England. They also provide full installation, training and support.

- Cost effective with high recovery performance

- An environmentally-friendly dry process

- Designed to operate in heavy industrial environments

- Multiple rotor options for tailored recovery applications